Products

Optimized Technical Solutions, LLC has various software applications and tools to help design, control, and monitor the performance of equipment for the natural gas industry. Please contact us for more information. We develop our software with four fundamental rules in mind. Developed software should be:

- Rigorous - It should conform to established standards and rules which will result in it performing as expected. This requires establishing sufficient test standards to ensure accurate and repeatable results.

- Reliable - It should be written to provide results under all circumstances without producing errors.

- Robust - It should handle abnormal conditions well. It should be designed to protect data and calculate with efficiency.

- Reusable - It should be written such that it is built in modular format. Reusable modules reduce the implementation time, increase the likelihood that prior testing and use has eliminated defects, and minimizes the amount of modifications required to implement new features and functions.

Product Details

Products currently available for immediate licensing include:

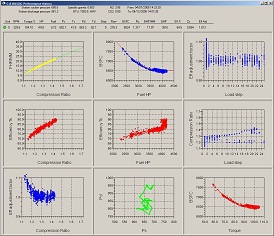

- EngineeringGraph/EngineeringDraw for VB6/VBA - This is an ActiveX control used to easily display graphic data. Features include automatic scale ranging for both maximum and minimum values, ability to identify individual lines on the graph with text that can be rotated, and tool tip text that identifies the X-Y coordinate location on the graph. The code has been optimized to update quickly with minimal recalculations and is therefore suitable for applications with frequent updates such as Human Machine Interfaces (HMI). Compatable HMI applications include RSView32 and WonderWare InTouch.

- EngineeringGraph/EngineeringDraw for .NET - This control is similar to the VB6/VBA version described above except it is written for Framework 4.0 and will work on Windows 64-bit operating systems. Additional features include an automatic contour generator.

- Parameter unknown tracker for Framework 4.0. This class tracks which parameter of a set of user defined parameters should be considered as the "unknown variable" with multiple parameters. For example, speed, torque, and power are all interrelated (power is proportional to speed times torque). If the user specifies values for speed and torque, the routine will now that the unknown parameter is power. Conversely, if power and speed are set, the unknown parameter will be automatically set to torque. Please contact us if you are interested in more information.

- Power Equipment Sizing and

Performance Indicator - This windows application is used to size

equipment and, when provided actual operating data, will compare

the actual performance to the expected performance. This will

help the operator identify and rectify performance problems in a

timely and efficient manner.

This application is currently under development in the Framework

4 environment for Microsoft windows. The application will model

the following components:

- Boilers

- Electric motors

- Wind, water, and steam turbines

- Gas turbines

- Reciprocating engines

- Pumps

- Compressors

- Generators

- Fans

- Heat exchangers

More details can be found in the class diagram below

Additional Products

Additional information is available on:

- Compression equipment sizing

- Compression equipment performance monitoring

- Gas regulation and measurement sizing, control, and monitoring

- Pipeline hydraulic modeling

- Excel add-in functions for routine calculations for the natural gas industry